Performance and Features:

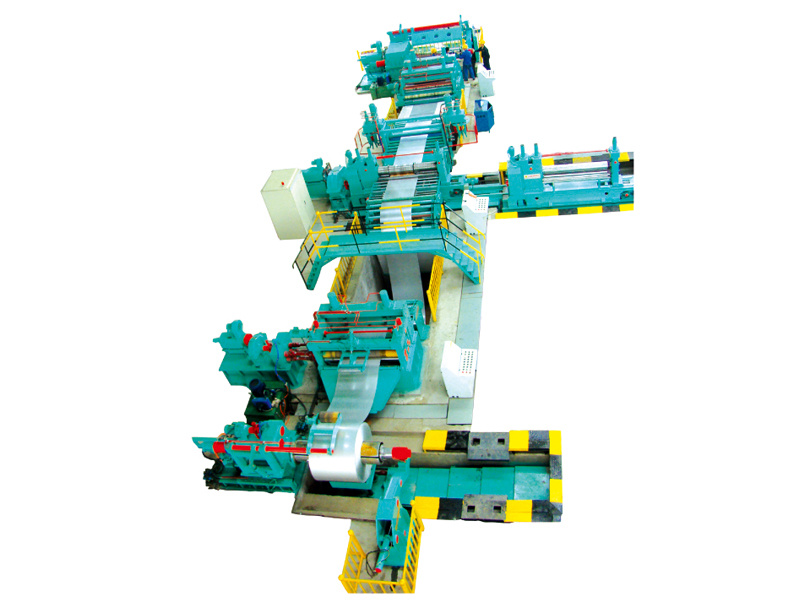

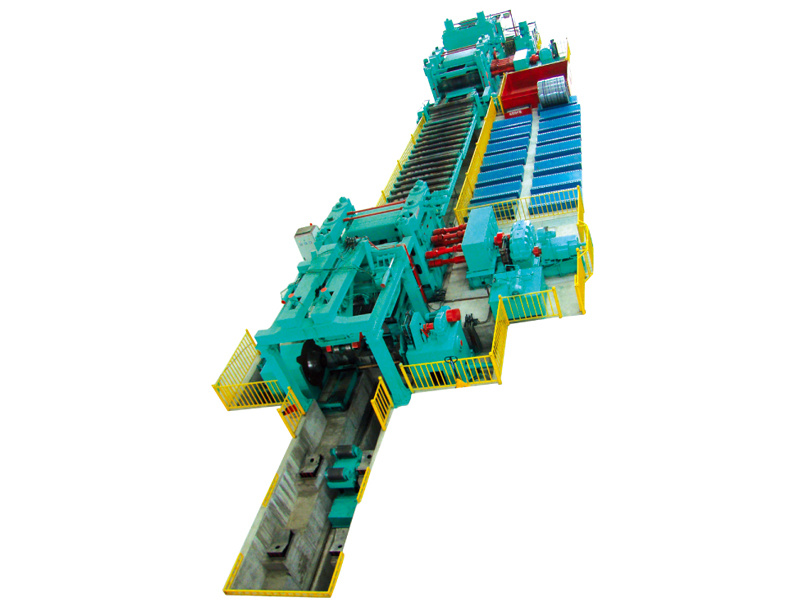

This series of production lines is used to process coils of different specifications, through uncoiling, initial leveling, head cutting, slitting, and rewinding into required fixed-width materials. The layout of this production line is reasonable, easy to operate, highly automated, and efficient in production. It can process various cold-rolled and galvanized sheets, silicon steel sheets, stainless steel sheets, color-coated sheets, aluminum sheets, and various metal sheets after electroplating or coating. It is widely used in the metal sheet processing industries such as automotive, container manufacturing, home appliances, food, packaging, and building materials. The production line mainly consists of equipment such as feeding carts, uncoilers, slitting machines, waste rewinding machines, head and tail cutting machines, tension control machines, and rewinders. Additionally, it is equipped with swing-type intermediate bridges, clamping devices, and correction devices between the machines. This production line is an automatic coil processing equipment that integrates machinery, electricity, hydraulics, and pneumatics.

This series of production lines is used to process coils of different specifications, through uncoiling, initial leveling, head cutting, slitting, and rewinding into required fixed-width materials. The layout of this production line is reasonable, easy to operate, highly automated, and efficient in production. It can process various cold-rolled and galvanized sheets, silicon steel sheets, stainless steel sheets, color-coated sheets, aluminum sheets, and various metal sheets after electroplating or coating. It is widely used in the metal sheet processing industries such as automotive, container manufacturing, home appliances, food, packaging, and building materials. The production line mainly consists of equipment such as feeding carts, uncoilers, slitting machines, waste rewinding machines, head and tail cutting machines, tension control machines, and rewinders. Additionally, it is equipped with swing-type intermediate bridges, clamping devices, and correction devices between the machines. This production line is an automatic coil processing equipment that integrates machinery, electricity, hydraulics, and pneumatics.

Performance and Features:

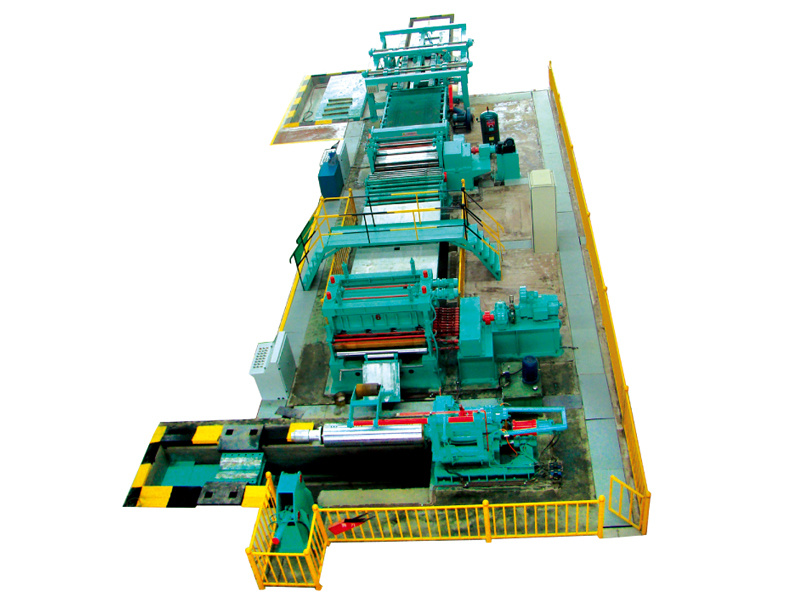

This series of production lines is used for different specifications of coils, which are unrolled, leveled, and cut into flat sheets of the required length and width. The production line mainly consists of a feeding cart, a single-arm uncoiler, a bridge machine, a hydraulic storage bridge, a correction device, a precision leveling machine, a servo length measuring machine, a shearing machine, a belt conveyor, a flipping drop rack, a stacking device, a discharge cart, a servo drive system, a hydraulic system, and more.

This series of production lines is used for different specifications of coils, which are unrolled, leveled, and cut into flat sheets of the required length and width. The production line mainly consists of a feeding cart, a single-arm uncoiler, a bridge machine, a hydraulic storage bridge, a correction device, a precision leveling machine, a servo length measuring machine, a shearing machine, a belt conveyor, a flipping drop rack, a stacking device, a discharge cart, a servo drive system, a hydraulic system, and more.

Performance and Features:

The flying shear production line uses highly reliable mechanical performance and a mature and stable electrical control system to achieve high efficiency and high-quality cutting of sheet materials. The entire line is leveled and cut continuously and quickly, with high dimensional accuracy, and a user-friendly human-machine interface ensures convenient operation.

The flying shear production line uses highly reliable mechanical performance and a mature and stable electrical control system to achieve high efficiency and high-quality cutting of sheet materials. The entire line is leveled and cut continuously and quickly, with high dimensional accuracy, and a user-friendly human-machine interface ensures convenient operation.

HR/pickling coil uncoiling-leveling-shearing-stacking line

Performance and Features:

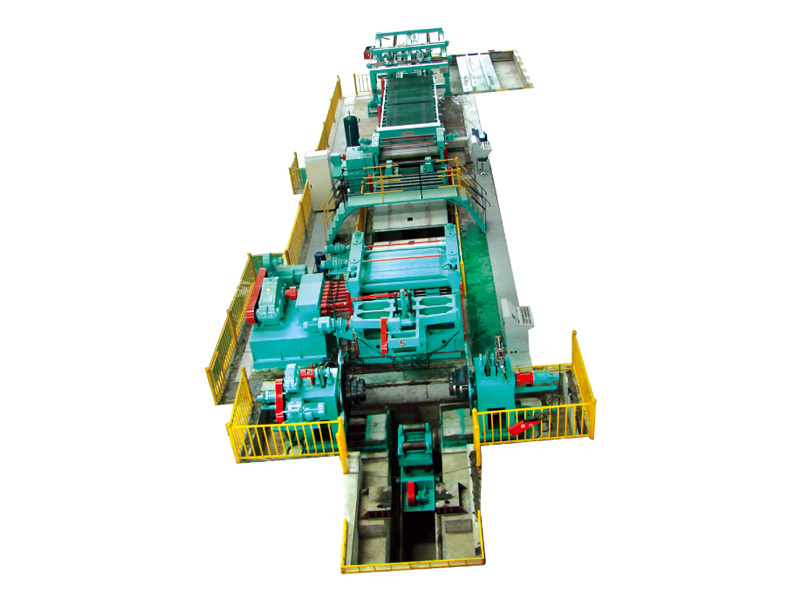

This series of production lines is used to process hot-rolled plates and pickled coil materials of different specifications, through uncoiling, leveling, and cutting into flat plates of the required length. The production line mainly consists of a feeding cart, a double-support uncoiler, a hydraulic shovel head pressing mechanism, a leveling machine, a deviation correction device, a precision leveling machine, a servo length measuring machine, a shearing machine, a belt conveyor, a flipping drop frame, a stacking table, a discharge cart, and supporting electrical control and hydraulic systems.

This series of production lines is used to process hot-rolled plates and pickled coil materials of different specifications, through uncoiling, leveling, and cutting into flat plates of the required length. The production line mainly consists of a feeding cart, a double-support uncoiler, a hydraulic shovel head pressing mechanism, a leveling machine, a deviation correction device, a precision leveling machine, a servo length measuring machine, a shearing machine, a belt conveyor, a flipping drop frame, a stacking table, a discharge cart, and supporting electrical control and hydraulic systems.

HR coil uncoiling-leveling-shearing-stacking line

Performance and Features:

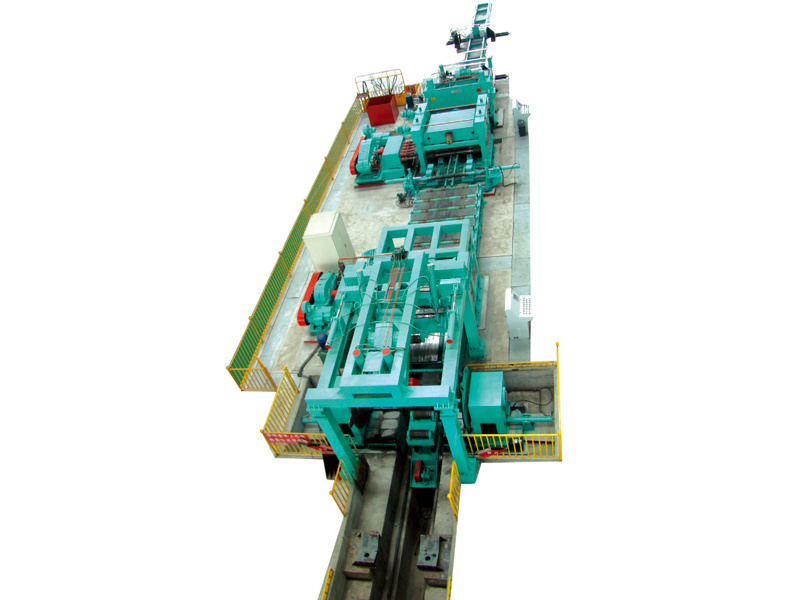

This series of production lines is used to process hot-rolled medium-thick plate coils of different specifications, which are uncoiled, leveled, and cut into flat plates of the required length. The production line mainly consists of a feeding cart, a double-support uncoiler, a hydraulic shovel head pressing mechanism, a preliminary leveling machine, a correction device, a precision leveling machine, a coding length-setting machine, a shearing machine, a stacking table, and supporting electrical control and hydraulic systems.

This series of production lines is used to process hot-rolled medium-thick plate coils of different specifications, which are uncoiled, leveled, and cut into flat plates of the required length. The production line mainly consists of a feeding cart, a double-support uncoiler, a hydraulic shovel head pressing mechanism, a preliminary leveling machine, a correction device, a precision leveling machine, a coding length-setting machine, a shearing machine, a stacking table, and supporting electrical control and hydraulic systems.

HR coil uncoiling-leveling-shearing-stacking line

Performance and Features:

This series of production lines is used to process hot-rolled medium-thick plate coils of different specifications, which are uncoiled, leveled, and cut into flat plates of the required length. The production line mainly consists of a feeding cart, a double-support uncoiler, a hydraulic shovel head pressing mechanism, a preliminary leveling machine, a correction device, a precision leveling machine, a coding length-setting machine, a shearing machine, a stacking table, and supporting electrical control and hydraulic systems.

This series of production lines is used to process hot-rolled medium-thick plate coils of different specifications, which are uncoiled, leveled, and cut into flat plates of the required length. The production line mainly consists of a feeding cart, a double-support uncoiler, a hydraulic shovel head pressing mechanism, a preliminary leveling machine, a correction device, a precision leveling machine, a coding length-setting machine, a shearing machine, a stacking table, and supporting electrical control and hydraulic systems.

If you are interested in us, please contact us!

Our staff will help determine the right solution for your application and provide a quote and detailed timetable.