Products

-

Hot Rolled Plate Pickling Line - Uncoiling - Leveling - Shearing - Stacking Production Line

-

Hot Rolled Sheet Uncoiling - Leveling - Shearing - Stacking Production Line

-

Hot Rolled Sheet Uncoiling - Leveling - Shearing - Stacking Production Line

-

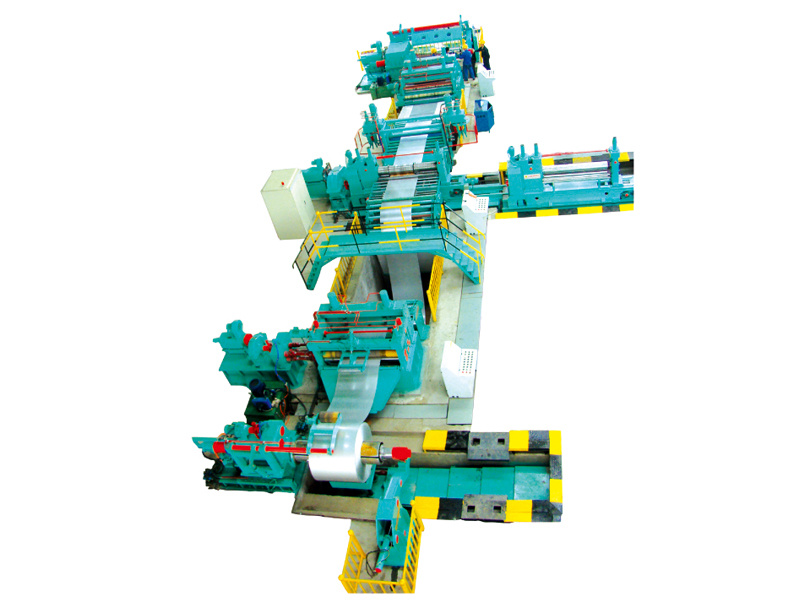

Hot Rolled Sheet Uncoiling, Slitting, and Recoiling Production Line

-

Stainless Steel Uncoiling - Leveling - Shearing - Stacking Production Line

-

Stainless Steel Uncoiling - Leveling - Shearing - Stacking Production Line

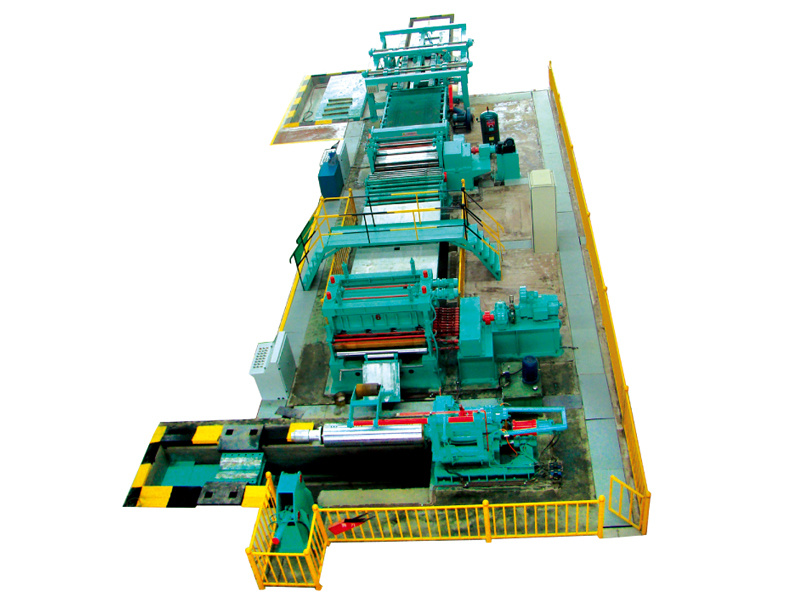

NC slitting line

This series of production lines is used to process coils of different specifications, through uncoiling, initial leveling, head cutting, slitting, and rewinding into required fixed-width materials. The layout of this production line is reasonable, easy to operate, highly automated, and efficient in production. It can process various cold-rolled and galvanized sheets, silicon steel sheets, stainless steel sheets, color-coated sheets, aluminum sheets, and various metal sheets after electroplating or coating. It is widely used in the metal sheet processing industries such as automotive, container manufacturing, home appliances, food, packaging, and building materials. The production line mainly consists of equipment such as feeding carts, uncoilers, slitting machines, waste rewinding machines, head and tail cutting machines, tension control machines, and rewinders. Additionally, it is equipped with swing-type intermediate bridges, clamping devices, and correction devices between the machines. This production line is an automatic coil processing equipment that integrates machinery, electricity, hydraulics, and pneumatics.

- Description

-

Performance and Features:

This series of production lines is used to process coils of different specifications, through uncoiling, initial leveling, head cutting, slitting, and rewinding into coils of the required fixed width. The layout of this production line is reasonable, easy to operate, highly automated, and efficient, capable of processing various cold-rolled and galvanized sheets, silicon steel sheets, stainless steel sheets, color-coated sheets, aluminum sheets, and various metal sheets after electroplating or coating. It is widely used in the metal sheet processing industries such as automotive, packaging boxes, home appliances, food, packaging, and building materials. The production line mainly consists of equipment such as a feeding cart, uncoiler, slitter, waste rewinder, head and tail cutting machine, tension control machine, and rewinder. Additionally, it is equipped with a swing-type intermediate bridge, clamping device, and correction device between the machines. This production line is an automatic coil processing equipment that integrates machinery, electricity, hydraulics, and pneumatics.

Technical Parameters:

Specification Model 0.3-3.0x800-2000mm Processing Materials Cold-rolled sheets, galvanized sheets, stainless steel sheets, automotive sheets Sheet Width 800-2000mm Sheet Thickness 0.3-3.0mm Coil Weight 20T Production Line Speed 100-180m/min Number of Strips 30 strips Floor Area 24mX9m Installed Capacity 300Kw As the product is continuously being improved, if there are inconsistencies between the sample technical data and the actual product data, the parameters of the technical agreement between both parties shall prevail. No further notice will be given.

Message

Please provide the following valid information and we will contact you as soon as possible.

If you are interested in us, please contact us!

Our staff will help determine the right solution for your application and provide a quote and detailed timetable.