How to choose a suitable slitting machine for yourself?

Release time:

2023-05-25

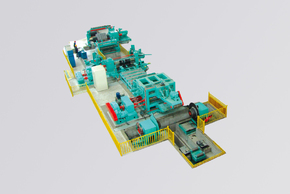

The slitting machine is a type of mechanical equipment used to longitudinally cut materials such as metal sheets and coils into strips. It is widely used in industries such as steel, construction, automotive, and electrical appliances. When purchasing a slitting machine, it is important to choose based on your own needs and actual circumstances. This article will introduce aspects such as cutting materials, cutting specifications, cutting precision, cutting efficiency, and safety, to help readers select a slitting machine that suits their requirements.

The slitting machine is a mechanical device used to cut metal sheets, coils, and other materials into strips longitudinally. It is widely used in industries such as steel, construction, automotive, and electrical appliances. When purchasing a slitting machine, it is necessary to choose based on one's needs and actual situation. Below, this article will introduce aspects such as cutting materials, cutting specifications, cutting precision, cutting efficiency, and safety, to help readers select a suitable slitting machine.

1. Cutting Materials

The cutting materials for the slitting machine include steel plates, aluminum plates, copper plates, galvanized plates, stainless steel plates, etc. Different materials require different slitting machines. Generally speaking, the thicker the material, the stronger the cutting capacity required for the slitting machine, and vice versa.

2. Cutting Specifications

The cutting specifications of the slitting machine include cutting width and cutting thickness. When selecting a slitting machine, it is necessary to choose the cutting width and thickness based on actual needs. If wider and thicker materials need to be cut, a slitting machine with greater cutting capacity should be selected.

3. Cutting Precision

The cutting precision of the slitting machine has a crucial impact on production efficiency and product quality. When choosing a slitting machine, it is necessary to consider cutting precision and stability. Generally, using a laser slitting machine can achieve higher cutting precision and stability, but the price is relatively high.

4. Cutting Efficiency

Cutting efficiency is one of the important factors affecting production efficiency. When selecting a slitting machine, it is necessary to consider cutting speed and efficiency. Generally, using a swing-type slitting machine can achieve higher cutting speed and efficiency. It is important to note that while pursuing cutting efficiency, cutting quality and safety must also be ensured. Excessively fast cutting speed and efficiency may lead to accelerated tool wear, material deformation, and even jeopardize personnel safety. Therefore, when choosing a swing-type slitting machine, it is necessary to balance cutting efficiency with cutting quality and safety, selecting equipment that meets actual needs.

5. Safety

The slitting machine is a relatively dangerous mechanical device, and safety issues must be taken into account. When selecting a slitting machine, it is necessary to consider its safety features, such as whether it has protective covers, emergency stop buttons, and other safety devices.

In summary, choosing a suitable slitting machine requires consideration of factors such as materials, specifications, precision, efficiency, and safety. Before purchasing, it is essential to fully understand one's needs and actual situation. Additionally, selecting a reliable slitting machine supplier is also very important. A supplier with a good reputation and service level can provide better pre-sale and after-sale services, ensuring the normal operation and maintenance of the equipment. Choosing a suitable slitting machine can improve production efficiency, reduce costs, and ensure product quality and safety.

Related News

If you are interested in us, please contact us!

Our staff will help determine the right solution for your application and provide a quote and detailed timetable.